As the world continues to focus on sustainable energy solutions, the use of hydrogen fuel cell vehicles is becoming increasingly popular. These vehicles offer a practical alternative to traditional gasoline-powered cars, but they require durable and reliable tubing to transport the hydrogen fuel safely. One of the critical materials used for hydrogen transportation is aluminum seamless tubes.

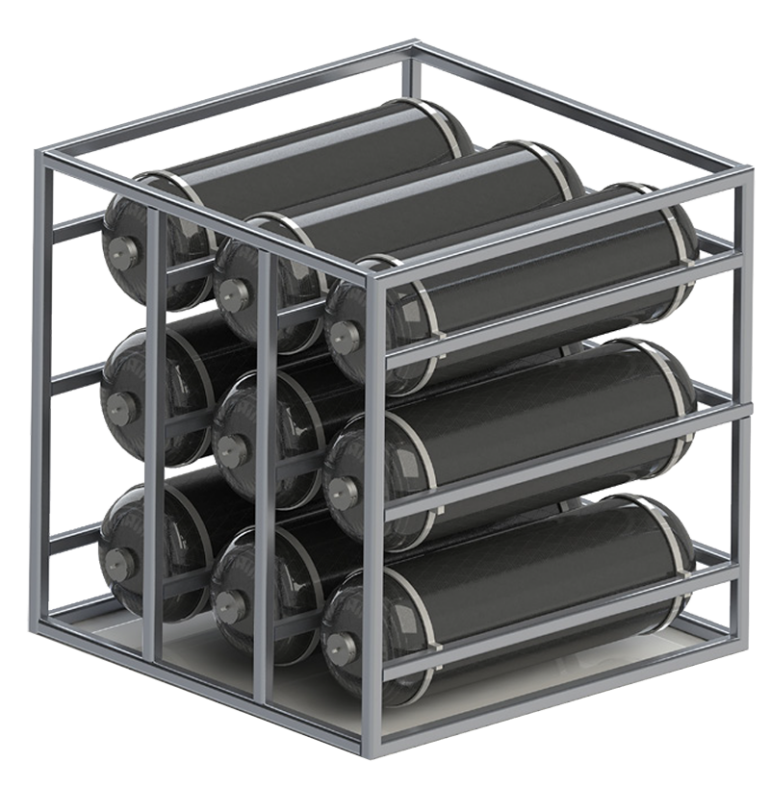

Aluminum seamless tubes are lightweight, strong, and corrosion-resistant, making them an ideal material for transporting hydrogen fuel. They can also be formed into complex shapes and designs, making them highly adaptable to different applications. Large-diameter aluminum seamless tubes, in particular, are becoming increasingly popular due to their ability to transport larger volumes of hydrogen while maintaining the same level of strength and durability.

Aluminum Seamless Tubes: The Ideal Material for Hydrogen Transportation

Aluminum seamless tubes are rapidly becoming the preferred material for hydrogen transportation, particularly in the automotive industry. The tubes offer several advantages over traditional materials such as steel, including higher durability, lighter weight, and greater resistance to corrosion.

One of the most significant benefits of using aluminum seamless tubes for hydrogen transportation is their strength. Aluminum tubes are exceptionally strong and have excellent tensile strength, allowing them to withstand the high pressure required for the transportation of hydrogen fuel safely. Additionally, the tubes have high fatigue resistance, ensuring that they can withstand the constant pressure changes that occur during hydrogen transportation.

Another advantage of aluminum seamless tubes is their lightweight design, which helps to reduce the overall weight of the transportation system. This reduced weight, in turn, improves the efficiency of the system, making it more economical and environmentally friendly. By using aluminum seamless tubes, hydrogen fuel cell vehicles can carry more hydrogen while reducing their overall weight, improving the vehicle’s range and efficiency.

Customizable Aluminum Seamless Tubes for Efficient Hydrogen Transportation

Customizable aluminum seamless tubes offer several benefits in the transportation of hydrogen fuel. One of the primary advantages of these tubes is their ability to be customized to specific applications. This flexibility in design allows for the creation of more efficient hydrogen transportation systems.

One way that customizable aluminum seamless tubes are used in hydrogen transportation is by allowing for optimal routing of the tubes. By designing the tubes to fit specific routes and areas, engineers can reduce the length of tubing required, reducing overall weight and increasing efficiency. The tubes can also be designed to fit in tight spaces and around obstacles, further increasing the flexibility of the transportation system.

Customizable aluminum seamless tubes can also be used to optimize the flow of hydrogen through the system. By designing tubes with different diameters, lengths, and bends, engineers can control the flow of hydrogen, ensuring that it flows smoothly and efficiently through the system. This efficient flow reduces the pressure drop, which in turn reduces energy consumption, making the transportation system more efficient.

Aluminum Seamless Tubes – An Essential Component for Efficient Hydrogen Transportation

Aluminum seamless tubes have proven to be an essential component for efficient hydrogen transportation. These tubes offer several benefits over traditional materials such as steel, including higher durability, lighter weight, and greater resistance to corrosion. In addition, the ability to customize aluminum seamless tubes to specific applications means that engineers can create more efficient and effective hydrogen transportation systems.

The demand for sustainable energy solutions continues to grow, and the transportation of hydrogen fuel is becoming increasingly important. The use of aluminum seamless tubes in hydrogen transportation is rapidly increasing, particularly in the automotive industry, where it is used to build fuel cell vehicles. These vehicles offer several benefits, including improved range and efficiency, as well as reduced emissions.

As the industry continues to evolve, it is likely that the use of aluminum seamless tubes in hydrogen transportation will continue to grow. Advances in tube technology, such as improved corrosion resistance and greater strength, will further enhance the efficiency and safety of hydrogen transportation systems.

In conclusion, aluminum seamless tubes are an essential component for efficient hydrogen transportation. The benefits of using these tubes include higher durability, lighter weight, greater resistance to corrosion, and flexibility in design. As the demand for sustainable energy solutions continues to grow, it is essential to continue developing and improving the technology used in hydrogen transportation.